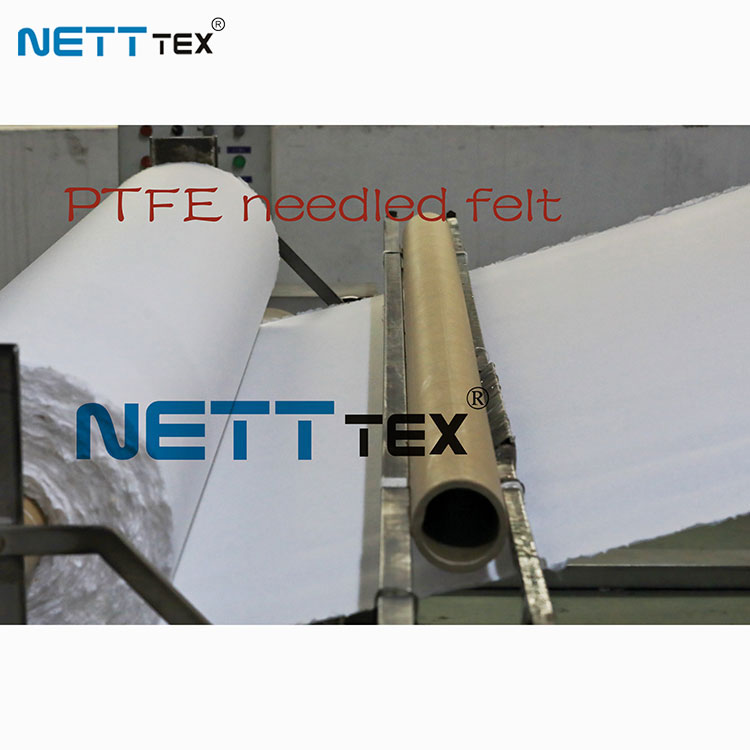

PTFE Needle Felt

As a professional high quality PTFE Needle Felt manufacturer, you can rest assured to buy PTFE Needle Felt from our factory and we will offer you the best after-sale service and timely delivery.

Send Inquiry

Introduction

As a professional high quality PTFE Needle Felt manufacturer, you can rest assured to buy PTFE Needle Felt from our factory and we will offer you the best after-sale service and timely delivery.

Benefits of our Needle Felt made of PTFE:

The nearly insoluble nature of 100% polytetrafluoron (PTFE) Needle Felt .its resistance to acid and alkali in a range of organic solvents are among its qualities. Moreover, polytetrafluoroethylene fabric has a low coefficient of friction and is easy to clean due to its extreme heat resistance. Perfect for use in hot weather conditions. The shrinkage rate is very low at high temperatures.

Description:

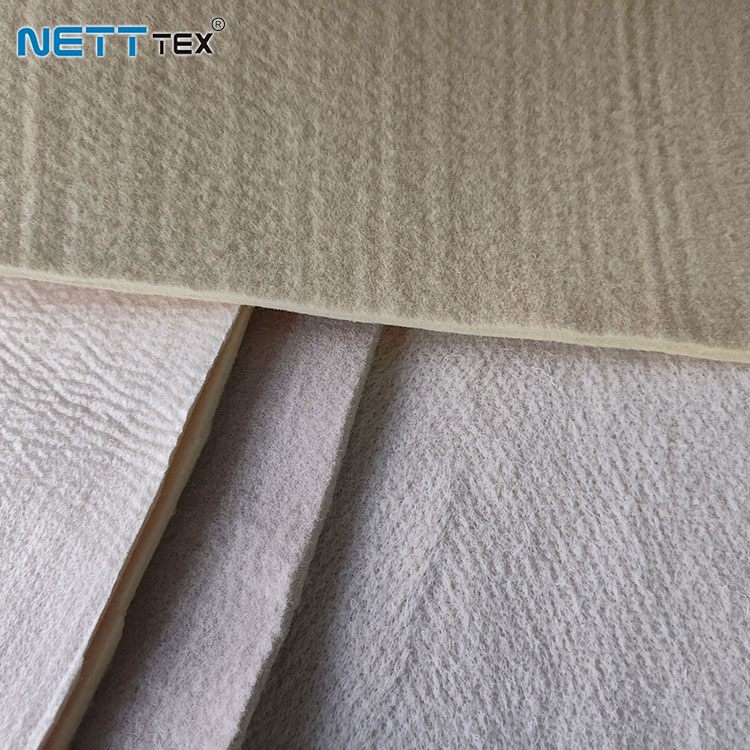

Material of PTFE Needle Felt:

PTFE scrim and PTFE staple fiber are combined to create PTFE needle felt. It is convertible into

The process of creating a 100% PTFE filter bag that can be used for a variety of operating conditions and filter fineness requirements typically involves using PTFE needle felt with membrane or PTFE impregnated needled felt after varying post-treatment.

100% PTFE resin from Dupont or Dakin.

Excellent high temperature resistance: For extended periods of time, Temperatures up to 220°C can be tolerated by PTFE Needle Felt without melting or degrading. PTFE is easier to clean because impurities are less likely to adhere to its surface due to its extremely low coefficient of friction.

Chemical resistance : PTFE Needle Felt has excellent chemical resistance and can resist the erosion of a variety of corrosive substances such as strong acids, strong alkalis, and solvents.

Wear resistance: PTFE Needle Felt resists wear and breaks less readily than other Filter Felt because of its high wear resistance.

Lasting: Because of their resistance to chemicals and temperatures, PTFE Needle Felt usually have a long lifespan.

High Filtration Efficiency: PTFE Needle Felt are able to effectively capture fine particles and particulates because of the fine nature of PTFE fibers.

Specification:

|

Product Name |

|||

|

Inspection item |

Technical index |

Detection data |

|

|

Width |

(1.0-2.2)m |

2.2 |

|

|

Weight |

(680-780)g/m² |

750g/m² |

|

|

Thickness |

(0.95-1.25)mm |

1.06 |

|

|

Air permeability |

L/M2.SEC@125pa |

72 |

|

|

Tensile strength |

Weft(N/5×20cm) |

>820 |

|

|

Weft(N/5×20cm) |

>820 |

||

|

Tensile elongation |

Weft (%) |

15 |

|

|

Warp (%) |

10 |

||

|

Service temperature |

|

250° |

|

|

Anti-acid |

|

Excellent |

|

|

Anti-alkali |

|

Excellent |

|

Application of PTFE Needle Felt:

One common application for 100% PTFE needle felt is in high corrosivity, high temperature, and high humidity working conditions. It is currently widely used in the chemical industry, medical waste incineration, and trash incineration.

They can efficiently collect and filter out liquid droplets and solid particles from the air in these applications, shielding the environment and machinery from corrosion and pollutants.

Several reasons to choose PTFE Needle Felt produced by NETT:

The company in line with the idea of "professional positioning, special development", the company specializes in the development of various kinds of fluorine polymer material fiber. At present, it has an annual output of 200 tons of PTFE filament and polytetrafluoroethylene sewing thread production capacity, 120 tons of polyvinylidene fluoride composite wire production capacity, and 50,000 square meters of PTFE needle felt production capacity, the output value can reach 50 million .

NETT directional environmental protection filtration field development of high temperature resistance, corrosion resistance, wear resistance, can seal the pinhole of PVC sewing wire, composite sewing wire products, welcomed by the majority of users. NETT adhere to the "market demand" as the technology development direction, we can produce a variety of specifications from 100D to 10000D filament yarn and sewing thread; in addition,we can also produce various specifications of colorful yarn and sewing thread products.

Suzhou NETT New Material Technology Co., Ltd. is the lead drafter of the standard "PTFE sewing thread for filter bag" of China Industrial Textile Association, participating in the drafting of two standards and three group standards.

NETT holds 19 independent intellectual property rights, including 4 invention patents

Since 2019, NETT has been recognized as a national high-tech enterprise in China and a science and technology private enterprise in Jiangsu Province. NETT is also a member unit of China Industrial Textile Association and China Environmental Protection Industry Association.

NETT has passed the ISO9000 quality management system and the ISO14000 environmental management system certification. The enterprise adheres to the brand development route, taking the high-end demand of the international market as the positioning. At present, the products have been involved in environmental protection, medical equipment, biological pharmaceutical, chemical, food, sports goods, building materials and other fields, and has achieved a stable market share.

In line with the development concept of "pragmatic and progressive, innovation and strong", Suzhou NETT New Material Technology Co., Ltd is willing to work with customers to make high-quality products, create first-class service, and become a trustworthy supplier to create value for you.

PVDF multifilament

Related products: